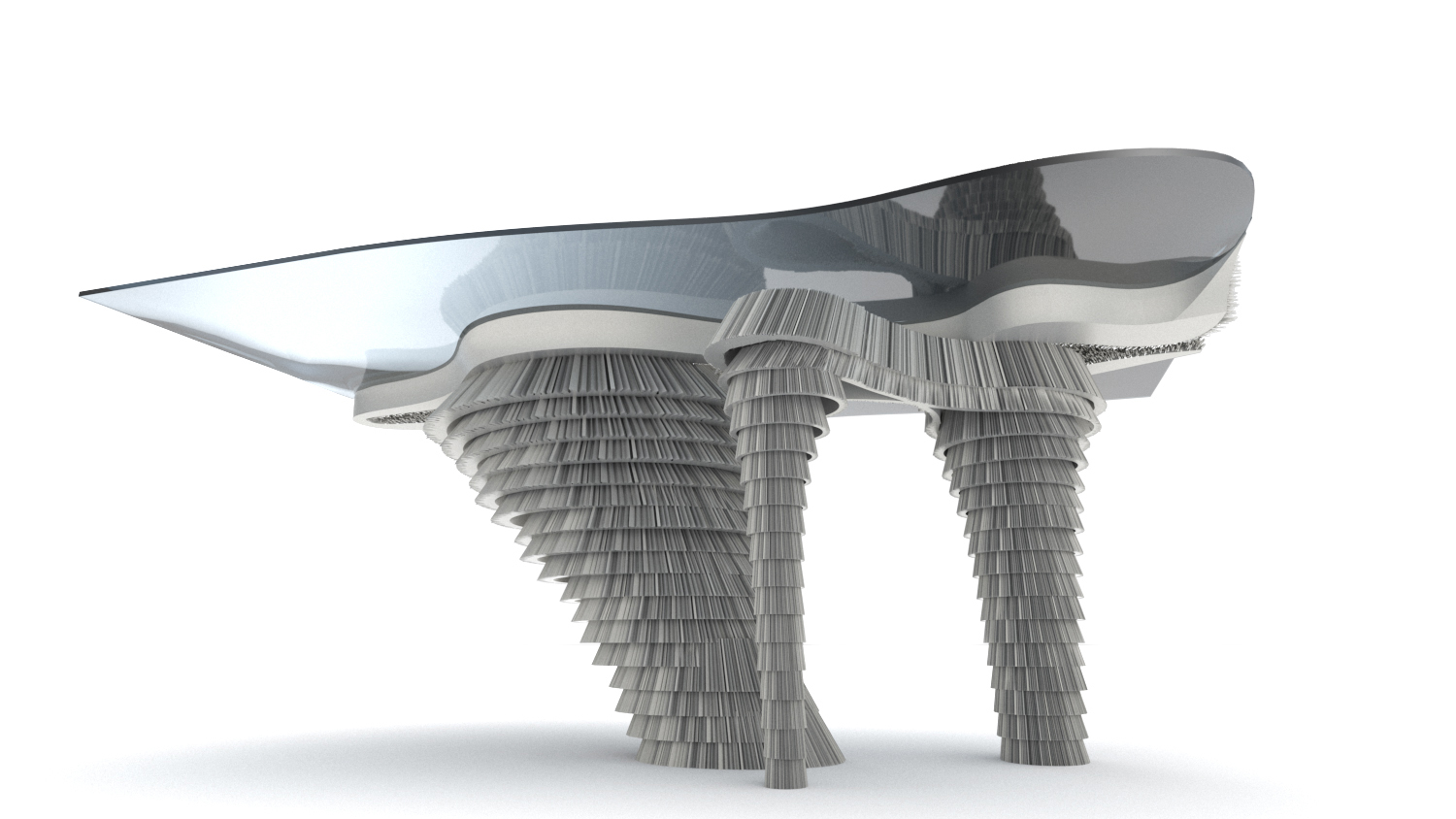

FLUFFY CUT

COLLABORATORS: ALI RAHIM, ANDY ZHENG

Fluffy Cut aims to create an aesthetic affect using materialization methods usually assumed to create things that are antithetical to adjective we chose. Thus, the aim of the exploration is to push the limits of precise material cutting techniques, mostly in 2D planes, to the point that we can create objects that imitate the qualities of “fluffy” or “furry” things. Therefore, we focused on studying laser, water and wire cutting, in order to realize their limiations and discover particular uses to aid in creating the affect of “fluffy” in the form of a dining room table. By doing this, we hope to gain a better understanding of the cutting techniques in the architetural field and open the conversation for these techniques to further tested and applied in the field.

Comprised of only cut metal and glass, this table is made up of varying thicknesses of materials, but all cut and produced in 2D cutting beds. Thus, we went about this assembly in layers. First, the legs we imagined being created out of water cut metal in varying thicknesses. With water cutting, you can change the filter at the end of the water jet that controls how much abrasive material is excreted along with the water. This process controls how rough the edges would be along the cut.

So, we saw an opportunity to create a fluffy affect through this cutting effect, an affect of fluffiness that you would see in something like a ruffled dress. Next, the inner layer simply uses a layered mass of thin metal pieces cut with variable thin extrusions. Finally, the glass is cut with water cut, using a very precise filter on the waterjet. The overall table showcases different fluffy affects to create an unique formation and aesthetic for a dining room table.